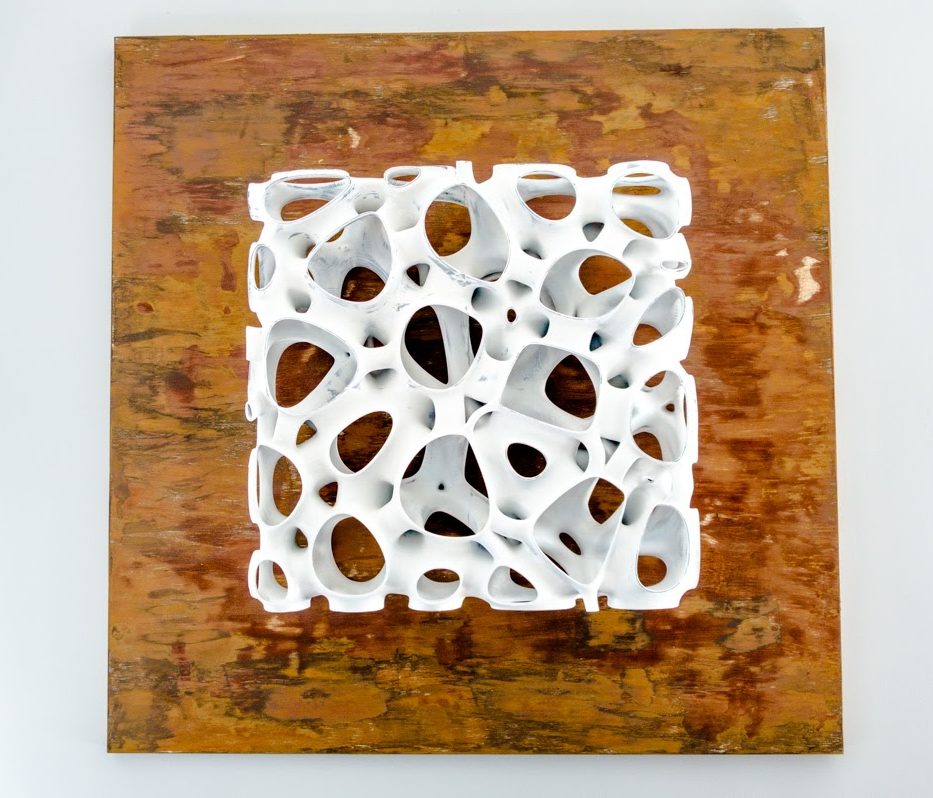

Hopper for Cocoa Nibs / Liquor Extraction

Chocolate making is messy business. One of the steps in nib-to-bar chocolate making is to extract the liquor from the nibs. We use a Champion Juicer. Inevitably, when you add nibs to the chute … a lot of them fly back up the chute and land all over the kitchen. So I built this hopper …

Continue reading “Hopper for Cocoa Nibs / Liquor Extraction”